About Us

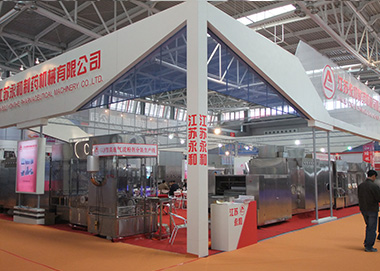

Jiangsu Yonghe was establish in early 1996,located in HaiMen economic development area,it is a professional manufacturing factory in designing & manufacturing pharmaceutical machine and packing machine.

Products

Jiangsu Yonghe is the strongest factory in designing&manufacturing by ownself in powder,oral liquid,freeze-drying product,ampoules,syrup etc linkage production line,also we are the most omniform factory to provide kinds of product,we have 9 series about 100 kinds of product,and we are passed the inspecting by National Pharmaceutical machinery product quality Inspecting Center,meets the requirement of “GMP”.

Service

Detail achievement perfect service makes the brand good faith to lead the development. With the policy of "establish brand by service, seek development by good faith, establish image by management, win market by quality", serve every customer wholeheartedly, serve domestic and foreign customers wholeheartedly.

Recruitment

"Yonghe" put forward the "use talents without sticking to one pattern", vigorously promote the "open, equal, competitive, merit-based" employment mechanism, no matter what position you are in, as long as you can give full play to your potential talents, as long as you have real talents, you may become the company's reuse of talents.

Contact Us

You are very important to us! In order to more quickly understand your needs, please contact us in a timely manner, we will arrange personnel to contact you as soon as possible, dedicated to your service!