Technological Innovation and Careful Manufacturing

Committed to make greater contributions to the development of pharmaceutical industry

USAGE & BRIEF INTRODUCTION

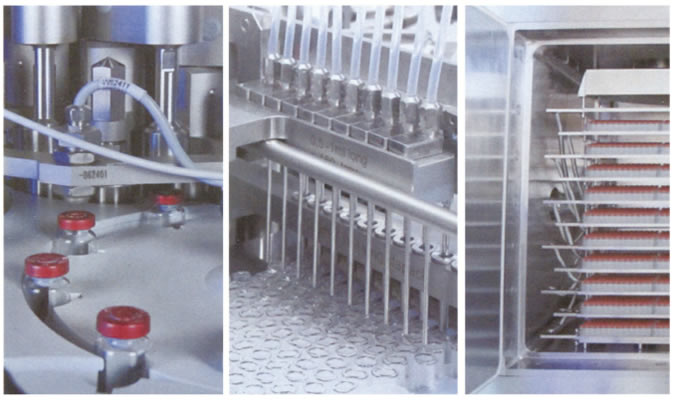

The machine conforms to "CGMP" requirement, suitable for vials washing, drying, sterilization and aseptic filling and plugging, made up of CLQ-C chain ultrasonic washing machine, KSM type glass bottles tunnel drying oven sterilizer, GGZ type high speed liquid filling &stoppering machine.

CHARACTERISTIC:

The line adopts advanced bucket transfer, modular cleaning, eleven WAG washing, machanical pushing bottle; Drying and sterilizing adopts hot wind circulation, thermal expansion connection,cooling water circulation, in-line mesh washing; Filling adopts servo motor driven ceramic metering pump for aseptic filling, rotating track plugging, glove isolator operation and sterile plugging linking.

This line features touch screen operation, PLC automatic control, on-line washing and on-line sterilizing, on-line tesing, over temperature alarm, no bottle no filling, on-line dosage adjustment, on-line automatically weighing,sterile linking dust particles inspecting hole and automatic counting functions,.

MAIN TECHNICAL PARAMETERS

1、Suitable bottle size:2~30ml vials(according to customer’s requirement)

2、capacity:200 bottles/min,300 bottles/min,400 bottles/min,600 bottles/min

3、total power:≤81KW,

4、power supply:380V,50Hz,3-phase 5-wire system

5、Overall size:13000×2500×2400(mm)

Recommended products